OUR STRENGTH

OUR STRENGTH

LEADING TECHNOLOGY

With state-of-the-art processing technology by world

standards, maximize added value, appeal and reliability of glass.

We support high quality with high technology.

Development of New Glass Materials

We propose and commercialize optical filters that meet your needs with

a consistent production system from material development, processing to productization.

Development

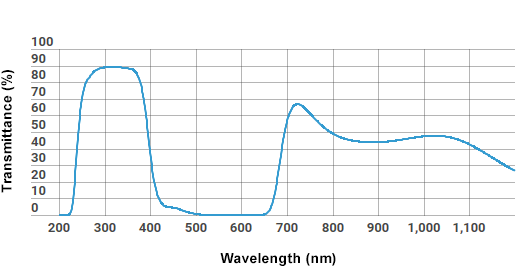

Visible light transmission and NIR 900nm band absorption glass LSA-900

- High transmittance at the visible wavelength and strong absorption at 900-1000 nm

- No change of optical characteristics depending on the angle of incidence

- No reflection of infrared laser at 900 nm (suitable for LiDAR and ToF)

Colored Glass Filters

55×55×2.5mmt

Glass Polished Lenses

φ60×25mmt

Detailed Data

Detailed Data

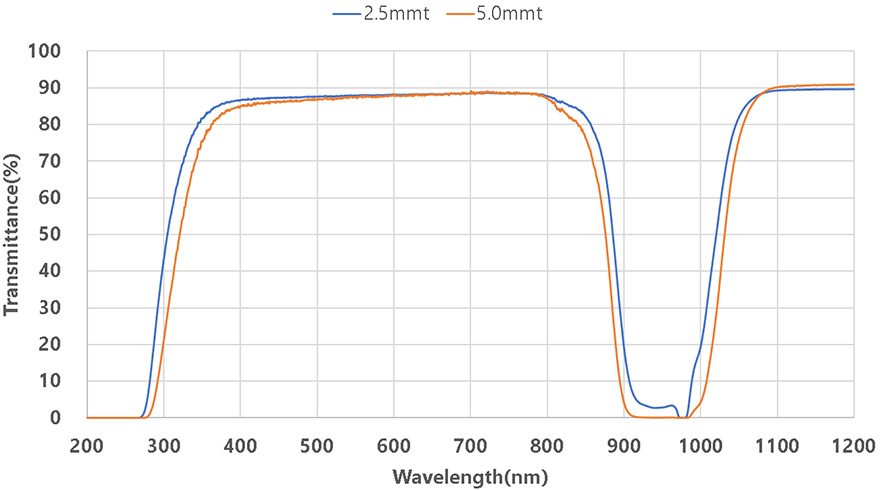

Transmittance (200nm-1200nm)

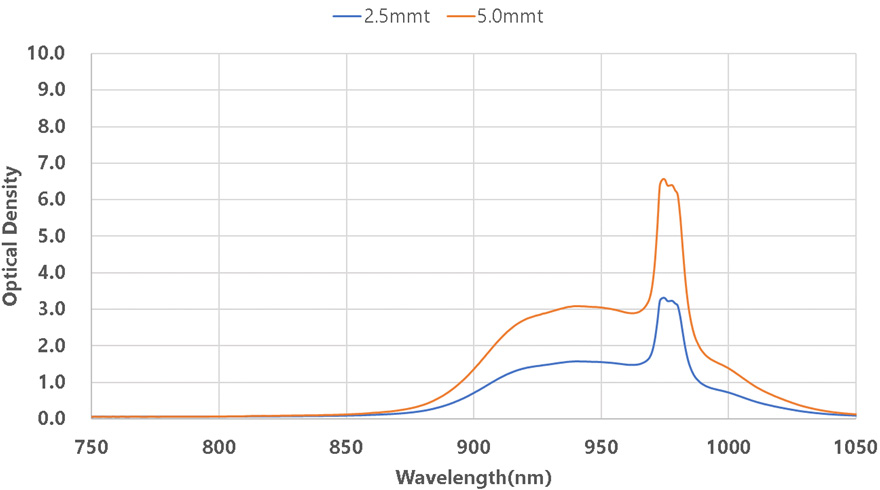

Optical Density (750nm-1100nm)

New material

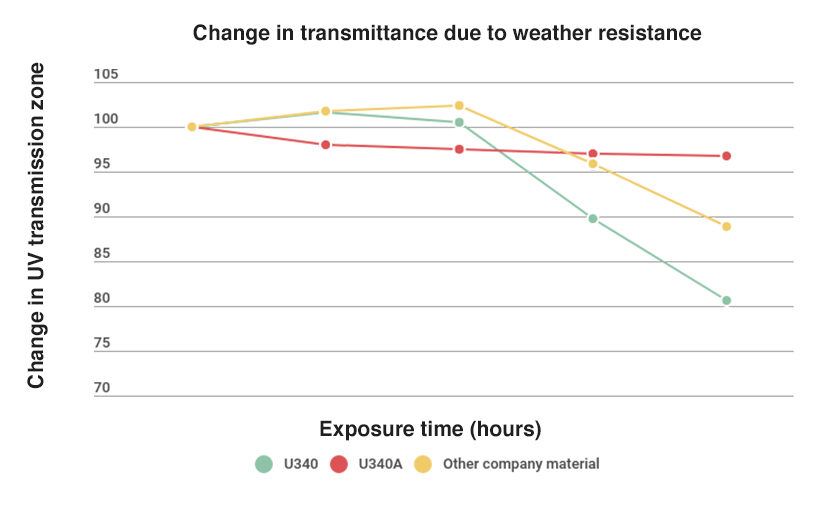

Excellent Weather Resistant UV Bandpass Filter U340A

- High resistance to solarization for high energy UV lamp and UV LED

- HOYA U340A outperforms the conventional U340. There is very little surface change in harsh environments.

New Material

New Material

Catalog Download

Catalog Download

Humidity Test

Accelerated test conditions: Relative humidity 65℃ / 90% RH, 168H

The initial transmitted light amount (260-400 nm) is set to 100, and the change in the light amount at the time of weather resistance evaluation is shown.

New material

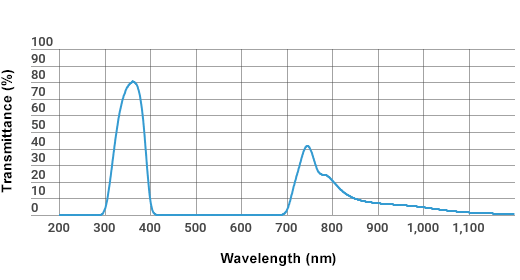

UV Band pass filter UL254S

- Excellent transmittance UV-C bandpass filter, UV transmitting, Visible absorbing

- High performance of solarization for high energy UV lamp and UV LED

- Heat tempered available

- Maximum dimensions: 300 (W) X 400 (L)

- Potential applications include: Sterilization, UV Fluorescent Analysis (Biomedical, Minerals etc.)

New Material

New Material

Catalog Download

Catalog Download

New material

UV Band pass filter UL365S

- UV band pass filter with ultraviolet transmission and visible absorption

- High resistance to solarization

- Heat tempered available

- Maximum available size: 400 (W) X 500 (L) - heat tempered

- Suitable for applications such as ultraviolet detectors, biomedical, theater lights, UV curing

New Material

New Material

Catalog Download

Catalog Download

New material

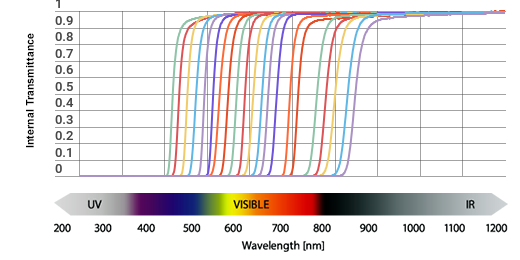

Sharp Cut Filters (W series)

HOYA GROUP OPTICS DIVISION has developed and released a new line of sharp cut filters with top quality and excellent optical performance. The ″W series″ meets the requirements of the market in all aspects.

New Material

New Material

Extensive Processing Technology

We have established our own processing consignment network with high quality and high technology both in Japan and overseas.

In addition to rectangles and round shapes, it is possible to provide products that make use

of high technical capabilities such as trapezoidal / cylindrical shape / inside diameter (perforated).

* The two colored glass filters in the center of pictures are

400 mm X 400 mm

Various type of filter size

In order to respond to your request, we provide optical filters in various shapes from small size to large size and from thin to thick. Please contact us for more details on availability which is dependent on the specific conditions required such as dimension, thickness, surface processing accuracy.

Integrated processing network from materials to finished product

In addition to selling colored glass filters as material and polished product, we have a network of consistent processing through completion which includes mounting in rings and packaging in small boxes. By doing so, we can offer finished products in the form of your request.

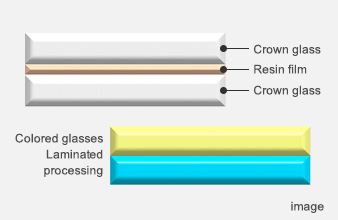

Laminated processing

We also handle laminated bonded products of colored glasses with unique characteristics achieved by overlapping the wavelengths of different colored glass filters. We also can provide special filters with characteristics that colored glass filters alone cannot guarantee by laminating a resin film or polarizing film between two substrates of crown glass.

Tempered glass

For transmission filters used for high-power light sources, requirements include increasing the glass strength to prevent damage due to sudden temperature changes. We can provide products with high strength reliability against large temperature changes by adding optimum heat strengthening process to various glass materials according to purpose of use. In addition, we can propose chemical tempering (ion exchange) according to your request. For chemical tempering process, glass types are limited. Please contact us for additional details.

Example 1:

Water immersion test at 230°C to 0°C. was passed by visible light region sharp cut filter

Example 2:

Freezing loading test at 200°C to -20°C. was passed by ultraviolet transmitted filter