Opto-Electronics Glass

OPTO-ELECTRONICS GLASSES

Anodic Bonding Glass (SD2)

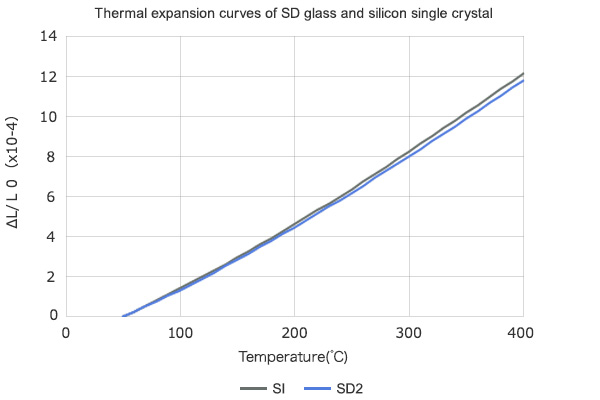

The thermal expansion characteristics are matched with silicon single crystal. Therefore, anodic bonding with little distortion can be performed over a wide temperature range.

Features

- Matching thermal expansion characteristics with silicon single crystal

By selecting the glass composition of aluminosilicate type (SiO2-Al2O3-Na2O type), thermal expansion was matched with silicon single crystal over wide temperature range. - Easy anodic bonding

The volume resistivity is reduced by adding a small amount of Na, and it has become glass composition that can perform strong bonding even at temperatures of 400 °C or lower. - Stable quality

The variation in the thermal expansion characteristics between the production lots is very small and stable. - Good to process

It can be etched with low concentration hydrofluoric acid aqueous solution, and the etched surface becomes mirror surface.

Example of Application

- 1) Semiconductor pressure sensor substrate

- 2) Acceleration sensor substrate

- 3) Nozzle part of ink jet printer

- 4) Glass for micromachining bonding

Characteristic

| Item | Unit | SD2 | Remarks |

| Thermal Properties | |||

| Coefficient of Thermal Expansion | X10-7/℃ | 32 | 30~300 ºC (thermal expansion meter) |

| X10-7/℃ | 33 | 30~350 ºC (thermal expansion meter) | |

| X10-7/℃ | 34 | 30~400 ºC (thermal expansion meter) | |

| X10-7/℃ | 35 | 30~450 ºC (thermal expansion meter) | |

| X10-7/℃ | 36 | 30~500 ºC (thermal expansion meter) | |

| Strain Point | ºC | 670 | 1014.5poise |

| Transformation (Tg) | ºC | 720 | |

| Sag Point (Ts) | ºC | 785 | |

| Mechanical Properties | |||

| Specific Gravity | 2.60 | ||

| Young’s Modulus | GPa | 87 | |

| Modulus of Rigidity | GPa | 35 | |

| Poisson’s Ratio | 0.24 | ||

| Knoop Hardness | 638 | ||

| Abrasion Factor | 44 | ||

| Chemical Resistance | |||

| HN03 Resistance | mg/cm2 | 0.08 | *1 |

| H2S04 Resistance | mg/cm2 | <0.01 | *2 |

| NaOH Resistance | mg/cm2 | <0.01 | *3 |

| Optical Properties | |||

| Refractive Index |

(Nd) | 1.531 | |

| Abbe-number | (νd) | 59 | |

| Electrical Properties | |||

| Dielectric Loss | (tanδ) | 0.010 | 20 ºC 1MHz |

| (tanδ) | 0.019 | 100 ºC 1MHz | |

| (tanδ) | 0.049 |

200 ºC 1MHz | |

| Dielectric Coefficient | 6 | 20 ºC 1MHz | |

| 7 | 100 ºC 1MHz | ||

| 7 | 200 ºC 1MHz | ||

| Volume Resistivity | X1012Ω・m | 4.1 | 20 ºC DC500V 1 minute |

| X1010Ω・m | 0.4 | 100 ºC DC500V 1 minute | |

| X107Ω・m | 3.8 | 200 ºC DC500V 1 minute |

- *1

- Indicate in weight reduction mg/cm2 per unit area when polished glass sample of 43.7 mm diameter (30cm2 on both sides) and 5mm in thickness was immersed in well stirred 80 °C 30% HNO3 aqueous solution for 50 hours.

- *2

- Indicate in weight reduction mg/cm2 per unit area when polished glass sample of 43.7mm diameter (30cm2 on both sides) and 5mm in thickness was immersed in well-stirred 80 °C. H2SO4: HNO3: H2O = 1:1:1 aqueous solution for 50 hours.

- *3

- Indicate in weight reduction mg/cm2 per unit area when polished glass sample of 43.7mm diameter (30cm2 on both sides) and 5mm in thickness was immersed in well-stirred 50 °C. 0.00N NaOH aqueous solution for 15 hours.

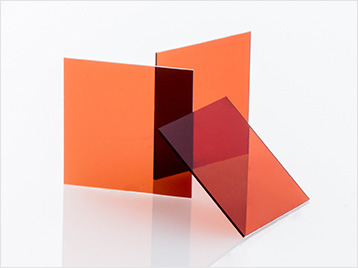

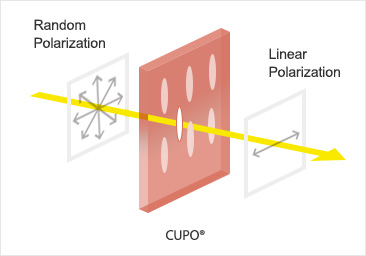

NIR Polarizer Glass CUPO®

It is polarizing glass (CUPO®) for near infrared light utilizing plasma absorption by copper fine particles. It is thin, achieves both high extinction ratio and low insertion loss, making it ideal as a component of small parts.

It is polarizing glass (CUPO®) for near infrared light utilizing plasma absorption by copper fine particles. It is thin, achieves both high extinction ratio and low insertion loss, making it ideal as a component of small parts.

Features

- Copper fine particle dispersed glass

- High extinction ratio

- Low insertion loss

- High reliability

Applications

- Optical isolator

- Optical modulator

- Wavelength selection switch

Specifications

| Band | O-band, E-band, S-band, C-band, L-band |

| Extinction Ratio | > 35 [dB] (Measured distance 5mm) |

| > 50 [dB] (Measured distance 300mm) | |

| Transmittnace (No AR coating) | > 90 [%] |

| Thickness (Standard) | 0.2 [mm] |

Both sides, Single side coating can be made

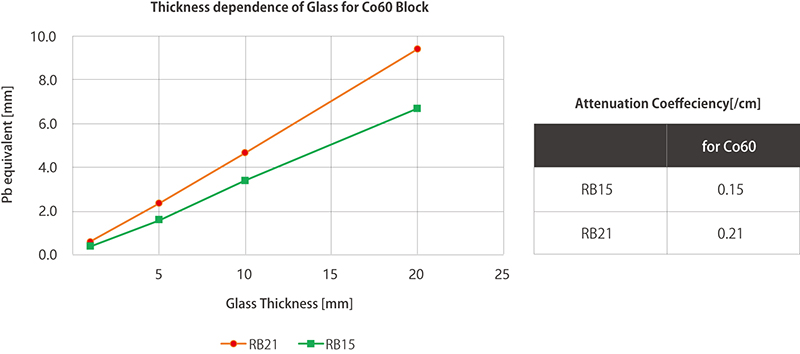

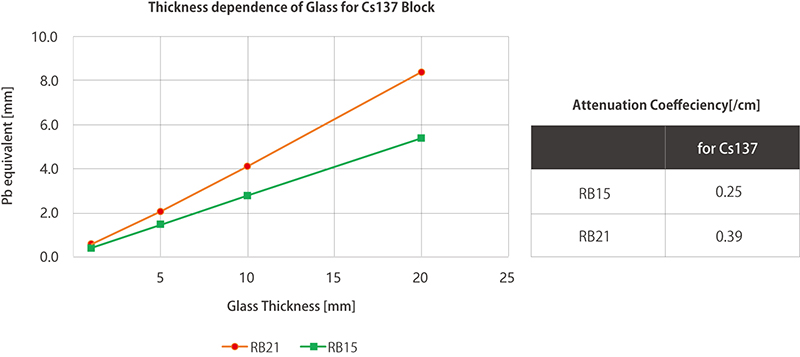

Radiation Shield Glass (RB series)

This material has two features both shielding radiation and visible light transmissive by doping PbO in the glass. This glass series can be corresponded to the type of radiation source and required dosage limit by controlling the doped material or thickness of the glasses.

This material has two features both shielding radiation and visible light transmissive by doping PbO in the glass. This glass series can be corresponded to the type of radiation source and required dosage limit by controlling the doped material or thickness of the glasses.

RB15 / RB21

Application

- 1) Observation window for radiation room

- 2) Lense for protective eyeglasses

Thickness dependence of Glass

- 1) Co60

- 2) Cs137

- 3) X-ray

![Figure:Thickness dependence of Glass for X-ray[200kV] Block](./index/images/XrayE.jpg)